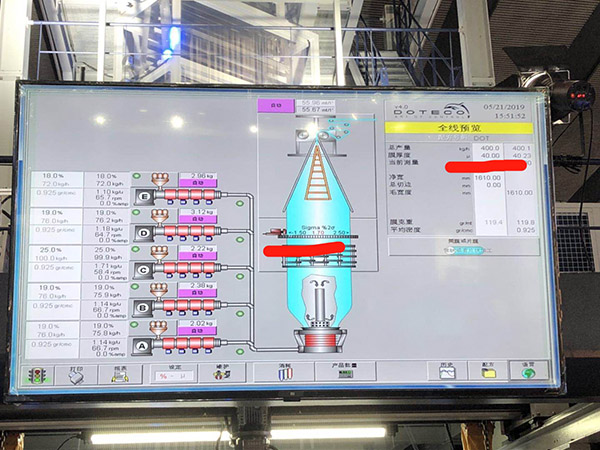

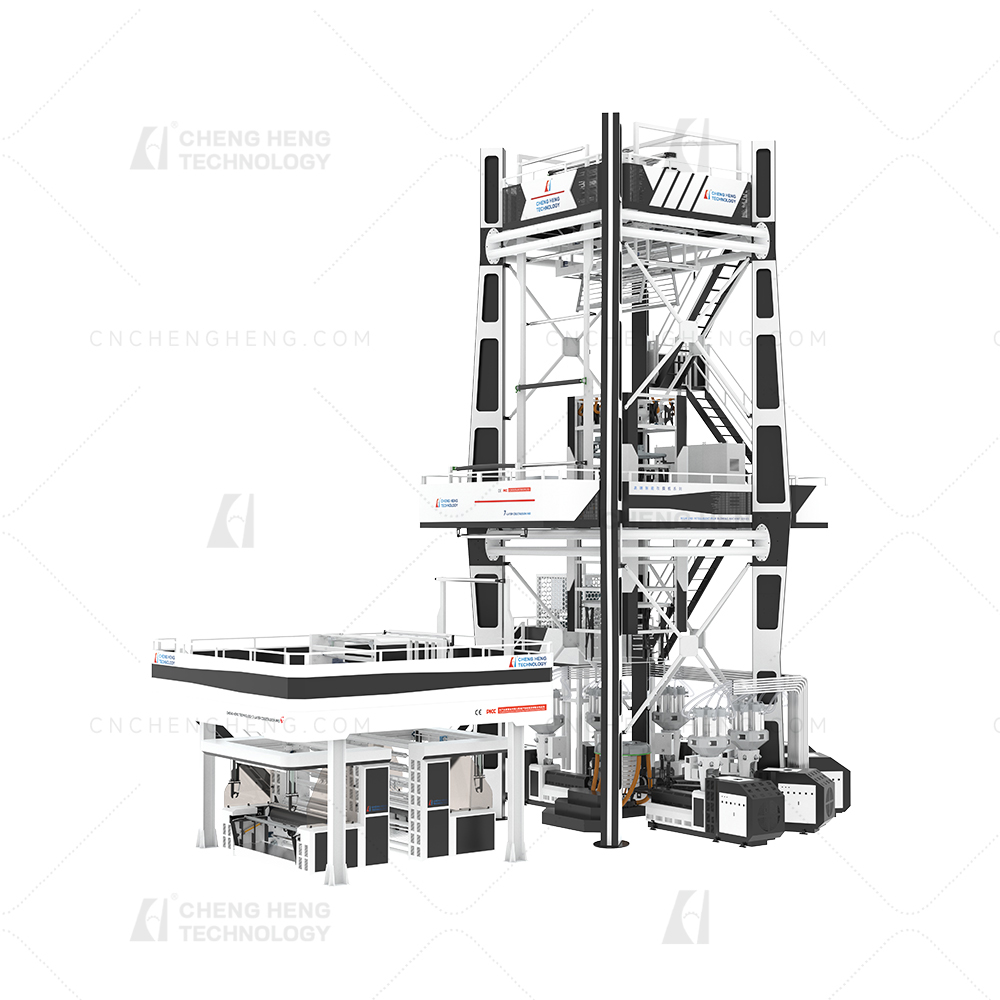

7-Layer Co-extrusion PRO film blowing machine

| Model |

55-50-50-50-50-50-55/1600 |

65-55-55-55-55-55-65/1800 |

|

| Width of the film |

700-1200mm |

900-1400mm |

|

| Thickness of the film |

0.0035-0.18mm |

||

| Output |

120-170kg/h |

140-250kg/h |

|

|

According to different width, thickness of film,die size and raw material characteristics to change |

|||

| Raw material |

PA/EVOH/LDPE/LLDPE/MLLDPE |

||

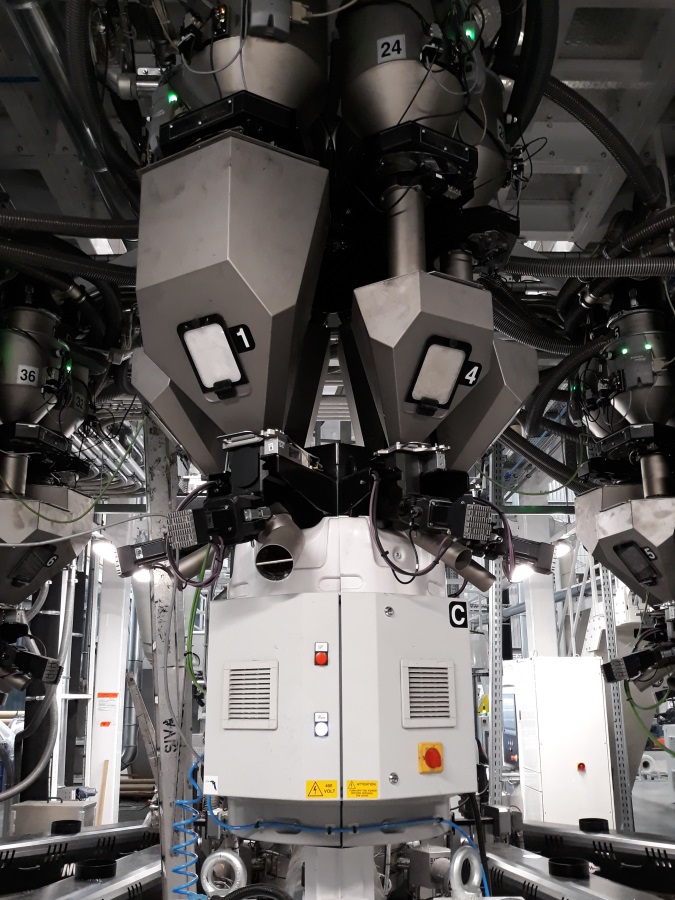

| Diameter of screw |

Φ55/50/50/50/50/50/55 |

Φ65/55/55/55/55/55/65 |

|

| L/D ratio of screw |

32:1 (With force feeding) |

||

| Gear box |

180# x 2 173# x 5 |

200# x 2 180# x 5 |

|

| Main motor |

30kwx 2 22kw x 5 |

37kw x 2 30kw x 5 |

|

| Die diameter |

300mm 400mm |

400mm 500mm |

|

Above parameters only for reference,could be customized according to customer needs,detailed data pls check actual object

Optional Device

Our 7 Layers Film Blowing Machine is ideal for various industrial applications, including food and beverage packaging, pharmaceuticals, and cosmetics. Featuring seven highly efficient polymer layers, this machine provides optimal film quality with unique properties to enhance its overall performance.

This machine is equipped with numerous features and advantages that make it an ideal choice for your business, including automatic temperature control, a precision microcomputer-controlled system, and a reliable cooling mechanism. Not only does the machine provide excellent performance, but it is also highly energy-efficient, reducing your environmental impact and operating costs. The primary advantage of this machine is that it produces high-quality adhesive films, making it perfect for food packaging, envelope sealing, and other applications requiring strong adhesive film properties. In addition, the films produced by our machine provide an excellent platform for branding and advertising purposes.

Our seven layers film blowing machine is highly user-friendly, with features that allow it to be easily customized to meet your specific production needs. It is equipped with an automatic alarm system, which alerts operators of maintenance requirements, minimizing downtime and ensuring optimal productivity.

Our engineering team has also designed the machine to be highly durable, ensuring it delivers reliable performance and minimizing repair costs. With a wide range of applications, this machine can produce films of varying thickness, width, and colors, providing the flexibility required for your business. The installation process is straightforward, ensuring that you can get your machine up and running in no time, with detailed instruction manuals provided for easy reference.

In summary, our 7 layers film blowing machine provides exceptional performance and reliability, ensuring that your business stays ahead of the competition. We pride ourselves on providing products and services that meet unique customer requirements, ensuring maximum productivity, profitability, and success in your industry.

Optional Device

Automatic Hopper Loader

Film Surface Treater

Rotary Die

Oscillating Take Up Unit

Two Stations Surface Winder

Chiller

Heat Slitting Device

Gravimetric Dosing Unit

IBC(Internal Bubble Cooling Computer Control System)

EPC(Edge Position Control)

Electronic Tension Control

Manual mechanics screen changer

Edge material recycling machine

Product Display