N-High Speed Mono-layer LDPE Film Blowing Machine

| Model |

75/1600 |

85/1800 |

90/2200 |

100/2400 |

110/2600 |

120/2800 |

| Width of the film |

600-1400mm |

1000-1600mm |

1400-2000 |

1500-2200 |

1500-2400 |

1800-2600 |

| Thickness of the film |

0.02-0.15mm |

|||||

| The max output |

70-150kg/h |

80-220kg/h |

100-270kg/h |

100-320kg/h |

100-380kg/h |

150-420kg/h |

| According to different width, thickness of film,die size and raw material characteristics to change | ||||||

| Raw material |

LDPE LLDPE MDPE CACO3 RECYCLING |

|||||

| Diameter of screw |

Φ75 |

Φ80 |

Φ90 |

Φ100 |

Φ110 |

Φ120 |

| L/D ratio of screw |

32:1 (With force feeding) |

|||||

| Gear box |

225# |

250# |

280# |

315# |

330# |

375# |

| Main motor |

37kw |

55kw |

75kw |

90kw |

110kw |

132kw |

| Die diameter |

φ350mm |

φ400mm |

φ500mm |

φ550mm |

φ600mm |

φ650mm |

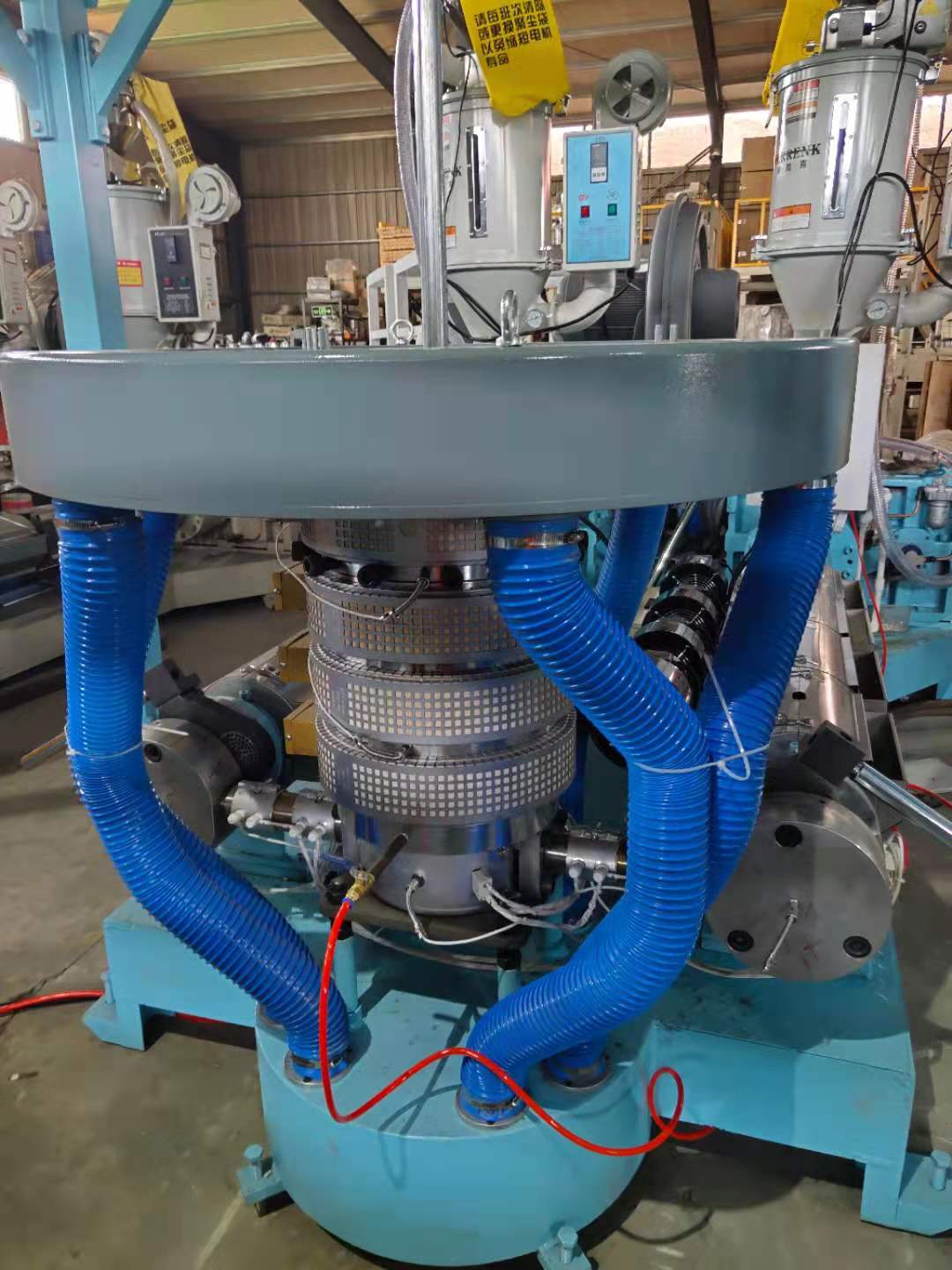

Product Description

High speed mono-layer LDPE film blowing machine is a popular machine that has been designed from the ground up with efficiency and productivity in mind.It delivers superior performance, reliability, and operational ease, making it an ideal solution for industries looking to streamline their production processes and boost their output.

This machine mainly use to produce big size film comes with a range of advanced features that set it apart from similar products on the market. Its high output rate and exceptional product quality are achieved through its advanced screw structure that delivers high-quality films with excellent mechanical strength. This makes it an ideal option for the production of food and non-food packaging, greenhouse films, and agricultural mulch films.

High speed mono-layer LDPE film blowing machine also boasts an weight control system that provides precise control over the production process.Its screw with force feeding and with water cooling , which avoid the phenomenon of bridging, and the feeding is uniform.And water cooling speeds up the temperature in the heating zone. And this mono-layer LDPE film blowing machine adopt double groove screw, better plasticizing effect, higher yield, more durable.

One of the critical advantages of the mono layer film blowing machine is its exceptional energy efficiency. Its state-of-the-art cooling system and smart control capabilities ensure minimal energy consumption, thus, reducing overall production costs. The machine is easy to install and integrate into existing production lines, with minimal downtime. Its high output rate and superior product quality make it ideal for large-scale productions, enabling producers to maximize their profits. Overall, the mono layer film blowing machine is a top-performing machine that delivers high-quality production output efficiently and reliably.